"The Great White Bird"

Links for larger images have been made where available. My Photo Archive has several other images, as well as different sizes of images seen here. Check it out!

Check this out! NASA's Quicktime movies of the XB-70!

Original WS-110 ... Compression Lift ... Early (Pre-Flight) History ... Flight History ... Midair! Midair! Midair! ... The Final Flights ... My Personal Summary

In 1959, North American Aviation was awarded a contract to build "Weapons System 110" (WS-110). On paper, the project's goals seemed insurmountable; not just the biggest craft ever to take to the skies, but is was to be the fastest as well, to cruise at 3 times the speed of sound, at a time when no plane had yet flown that fast.

During the Second World War, as the development of bombers became a science, it was an accepted fact that bombers would fly slower and lower than fighters. Fortresses, Liberators and Lancasters were simply armed to the teeth and sent out with fighter escort. Where ranges were too far for fighter escort, the bombers simply grouped together and fired back at attacking fighters. While this wasn't an entirely ineffective technique (B-17's claimed over 6,500 enemy fighters), it still caused horrific casualties (more than 5,000 B-17's were lost in combat).

But following the war, with better engines and designs, the new B-36

"Peacemaker" could fly as high, if not higher, than jet fighters of the day,

especially when four J47 jet engines were added to the design.

And, at very high altitudes, an interesting situation developed: with their

But following the war, with better engines and designs, the new B-36

"Peacemaker" could fly as high, if not higher, than jet fighters of the day,

especially when four J47 jet engines were added to the design.

And, at very high altitudes, an interesting situation developed: with their

much larger and more lightly-loaded (per square foot) wing, at altitude, the

B-36's could actually outmanuver the F86 Sabre! And the development of

Boeing's latest bomber, the B-47 "Stratojet" brought to the USAF a bomber

that not only had fighter-like top speeds and climb abilities, but looked

like a fighter, too! Suddenly, the old mantra of "low and slow" stopped

making sense. While no one was advocating a bomber that could dogfight, on

the other hand, development of a bomber that couldn't be hammered on from

above didn't seem unrealistic.

much larger and more lightly-loaded (per square foot) wing, at altitude, the

B-36's could actually outmanuver the F86 Sabre! And the development of

Boeing's latest bomber, the B-47 "Stratojet" brought to the USAF a bomber

that not only had fighter-like top speeds and climb abilities, but looked

like a fighter, too! Suddenly, the old mantra of "low and slow" stopped

making sense. While no one was advocating a bomber that could dogfight, on

the other hand, development of a bomber that couldn't be hammered on from

above didn't seem unrealistic.

While it was clear that Boeing's B-52 would not be able to outpace jet fighters, it was only considered an interim solution. In the shortest term, Convair had been tasked with building the B-58 "Hustler" as a medium size, Mach 2 bomber (although the B-58's abilities at Mach 2 would be limited due to the amount of fuel it consumed -- almost four times as much fuel at Mach 2 as at just under Mach 1!). With performance continuing to climb, it was clear that new generation of strategic bomber was required, culminating in the Request for Proposal (RFP) for "Weapons System 110."

The original WS-110 competition had boiled down to a competition between Boeing and North American. Although shaped differently, both of the original submissions had the following in common:

Takeoff weight of 1,000,000 pounds

Takeoff weight of 1,000,000 pounds

Large detachable portion of wing to allow for a Mach 3 "dash to

target"

Large detachable portion of wing to allow for a Mach 3 "dash to

target"

Mach 3 "dash" ability only

Mach 3 "dash" ability only

Were far too large to use existing USAF facilities designed for the

B-52

Were far too large to use existing USAF facilities designed for the

B-52

before the WS-110 shed its wings ... and

after

before the WS-110 shed its wings ... and

after

Needless to say, these proposals were rejected by the USAF, which sent Boeing and North American back to the drawing board.

However, during the later phases of the design process, both companies realized that designing an aircraft to actually cruise at mach 3 wasn't really that much more demanding that designing one that only had a "dash" capability.

Both teams went back to the drawing boards with what were the final requirements for the contract, which were:

Cruise Speed of Mach 3 (2,000mph)

Cruise Speed of Mach 3 (2,000mph)

Cruise Altitude of 70,000 feet

Cruise Altitude of 70,000 feet

A "shirtsleeve" environment for the

crew.

A "shirtsleeve" environment for the

crew.

50,000 pound payload

50,000 pound payload

A range of 7,500 miles

A range of 7,500 miles

Sized such that existing runways, hangars,

etc. that had already been built for the B-52 could be used without further

modification.

Sized such that existing runways, hangars,

etc. that had already been built for the B-52 could be used without further

modification.

Have flying characteristics suitable for

use with average USAF line crewmen.

Have flying characteristics suitable for

use with average USAF line crewmen.

Boeing's design was essentially very similar to the later SST; that is, essentially a delta with 3 engines (each mounted in its own pod) under each wing.

North American engineers pored through every aerodynamic study they could

find, looking for anything that could be applied to a large, triplesonic

bomber. They came across a forgotten NACA (now NASA) research paper about

"Compression Lift." This paper described how a conical body

underneath the center of a wing would push the air to the side, increasing

pressure under the wing section (thereby increasing lift!) with far less

drag than simply increasing the size of the wing itself. To illustrate the

concept, imagine a cone (like an ice cream cone). Then cut it in half

lengthwise, so now you have a half cone that has a flat surface from tip to

tail. Now imagine that half cone travelling through the air, flat side up,

with the "belly" of the cone on the bottom. As it travels through the air,

the "belly" will push the shape upwards. [Ed. note:it can be a bit

confusing; it certainly took me a long time to figure it out!]

In flight, the XB-70 could lower the outer wing sections either 25 degrees

for flying from 300 knots to Mach 1.4, or a

severe 65 degrees for speeds from Mach 1.4 to Mach 3+. Measuring just a bit

over 20 feet at the trailing edge, these wingtips represent the largest

movable aerodynamic device ever used.

Lowering the wingtips had three distinct effects on the XB-70.

Along with the wingtips, the six J93 engines, bomb bay, and landing gear were all contained in a

conical shape designed to enhance shockwave management. Overall, the XB-70

has the best lift-to-drag ratio of any manned airplane ever built, being

bettered only on the unmanned D-21 drone, an airframe designed to be

air-launched, fly at one speed and altitude, and then self-destruct (thereby

not needing to land).

By 1961, following the shooting down of the U-2 flown by Gary Powers over

Russia, it became obvious that the performance of surface-to-air

missiles was improving much faster than that of manned aircraft.

Following long, loud, and bitter debate, it was decided that the XB-70 would

not be a viable bomber platform, and the XB-70 program, as such, was

canceled. Development of the F-108 Rapier, intended as a fighter

escort to the XB-70, was also canceled.

Replacing the production bomber program was a limited program calling for

three XB-70 prototypes to perform high-speed flight research. Although this

vastly downsized program would have to carry the entire financial burden for the

development of the XB-70's radically new construction techniques, as well as

the J93 engine, the research data the program would gather would be

vitally important for the future SST and other military projects. NASA and

the Air Force would jointly manage and share the data garnered from the

XB-70.

To help limit costs, a number of non-aerodynamic changes were made to the

XB-70. Positions for the navigator and bombardier were removed, leaving

the XB-70 with just a pilot and co-pilot. The computerized

navigation and bomb-guidance systems were replaced by the bare minimum

instrumentation needed to fly safely. In fact, only one TACAN (Tactical Air

Navigation) system was installed, which later proved a great annoyance

to the XB-70 pilots. On one occassion, the failure of the TACAN unit led to

the inadvertent "booming" of Las Vegas, Nevada, when the XB-70 literally got

a hundred miles off course in a matter of minutes!

All three XB-70's were intended to be slightly different from each other.

The first XB-70 (referred to as AV/1 (Air Vehicle/1) or Ship 1) was built

entirely from wind tunnel results and initial computer-generated models (at

this time, the computer modelling took almost 18 months to complete!). AV/2

would be slightly modified based on further computer modelling and early

experiences with AV/1. The third airframe, AV/3, would have greater changes

based on additional modelling, and extensive flight data gathered from

the first two aircraft. The astute observer will notice that the 6' wind

tunnel model at the Smithsonian (National Air and Space Museum) is actually

of AV/3 (that is, it's a modified version of AV/2 -- note the canard angles).

Constructing the XB-70 required new fabrication techniques, reflecting the

production-oriented original design. Extensive use of costly titanium and

composite materials would have resulted in a bomber too expensive for mass

production, so North American decided to use a stainless steel honeycomb

construction -- something that had never been tried before. To keep the

weight down, the honeycomb itself was formed of stainless steel just .002"

thick! (for perspective, this was the TOLERANCES (variation allowed) in the

holes drilled in the frames of WWII fighters to lighten them!) One

production manager, after seeing the specifications and being assured they

were correct, exclaimed, "that's not metal, that's FOIL!" Welding such thin

materials was impossible, so a brazing technique had to be developed to

assemble the honeycomb structures. Titanium was used in certain

heat-critical areas, but overall, the expensive (and difficult to work with)

metal makes up only 9 percent of the Valkyrie's structure.

In front of an enormous crowd, General Fred Ascani stands at a podium,

first off, thanking all the people who have put their effort into the B-70.

From the dark shadow of an open hangar, far above the ground begins to

appear a graceful, swan-like neck of the B-70. Beneath it, the tug

struggles with the bulk of the airplane, and serves to frame the scale of

the great bird. As more and more of the B-70 emerges into the desert

sunshine, many in the crowd who have not seen the B-70 before take in a

collective gasp of amazement. Even General Ascani, the Project Director for

the B-70, is overwhelmed by emotion at this, the first public unveiling of

years of work.

Al White and Colonel Joe Cotton begin their pre-flight inspection of the

Valkyrie. Today's plan isn't a taxi test, or an engine run-up. White and

Cotton will lift the XB-70, the heaviest plane ever built, into the skies

above the Mojave Desert and fly from North American's Palmdale ("Plant 42")

facility to Edwards Air Force Base, the Air Force's Flight Test Center

(AFFTC).

And this is no ordinary flight plan! Once the Valkyrie is over Edwards AFB,

it calls for retracting the landing gear, and accelerating the XB-70 beyond

the speed of sound at 30,000 feet over the desert. In doing so, North

American Aviation will receive a $125,000.00 bonus from the Air Force.

At 6:10, White and Cotton climb aboard the Valkyrie to begin the pre-flight

checklist. 35 minutes later, engine number one is started and brought up to

operating temperatures. Just moments later, in the process of starting

engine number two, caution lights go on in the cockpit indicating a failure

in the engine's cooling loop. Both engines are shut down, and a few minutes

later, the problem is tracked down to a circuit breaker that is reset. The

process of starting the engines is begun anew at 7:14 and goes off without a

hitch. Finally, with 132,000 pounds (the weight of an SR-71!) of fuel

indicated, the XB-70 begins taxiing towards the runway. This is a delicate

affair, because the XB-70 has demonstrated a major problem with braking at

low speeds (a violent chatter that caused the XB-70's braking distance from

just 5mph to be 400 feet!), making maneuvering a tedious affair. During

taxiing, the XB-70 exhibits another trait -- with the pilots far in front of

the nose wheel, they bob up and down as the nose wheel rides over the

concrete joints in the taxiway. Combined with the long neck of the Valkyrie,

the nickname "Cecil" (referring to the ditty "Cecil the Seasick Sea

Serpent") seems particularly apt and was adopted by many of the people

involved with the program.

At 8:51, the XB-70 was over Edwards, and, having met up with all the chase

planes involved, Cotton retracts the landing gear. A minute later, waiting

for the retraction indicators to go "green," a chase plane calls out that

the retraction had failed. The right side main gear had stopped midway

through the retraction sequence.

In order to be compact and save space, the XB-70's main landing gear used a

complex sequence of motions. From an extended point, the wheel assembly

would first rotate 90 degrees (becoming perpendicular to the normal

direction of travel). Then, the unit would be rotated 90 degrees

vertically, so that rear set of wheels were almost touching the top of the

gear's main strut. At this point, the main gear would rotate backward until

it was level within the fuselage.

Now, however, the main landing gear legs had stopped after only completing the

first motion (rotating perpendicular to the direction of flight). The chase

plane reported seeing blue streaks on the fuselage behind the gear doors,

and that some kind of fluid was continuing to leak out. A leak in the

hydraulic system was the suspected culprit, but in mid-flight, the only

thing to do was to re-extend the landing gear before a loss of pressure made

it impossible to do so. Cycled back to the extended position, the gear

locked itself back into place, and the Valkyrie continued on her alternate

flight plan, proceeding with some low speed handling tests, which showed

stability and control to be more than acceptable -- it was better than the

B-52!

Half an hour later, the number three engine was showing 108 percent rpm, and

was shut down. White and Cotton then proceeded to line up for landing on

the 15,000 foot runway at Edwards. Almost 110 feet in front of the

landing gear, combined with the nose-up attitude required to land the big

Almost immediately trouble set in. Although White and Cotton couldn't sense

it, a pressure surge in the brake system had locked the rear wheels of the

left side main gear, causing a fire. Notified of this, White let the

Valkyrie coast to a stop, using 10,800 feet of runway. Once the fire was

extinguished, repairs had to be made before the XB-70 could be taxied away.

On October 5th, 1964, White and Cotton again took the Valkyrie into the

air, again with the intention of achieving supersonic flight (This time,

there would be no bonus, but following this flight, North American would be

assessed penalties for each additional flight until the XB-70 broke the

sound barrier). Following takeoff, with a chase plane on each side, the

landing gear was retracted, then lowered, then retracted again without a

problem. With the landing gear up and stowed away, the XB-70 climbed up to

28,000 feet and accelerated to 600mph (Mach .85) in preparation for

supersonic flight.

Here again gremlins struck the Valkyrie. The primary hydraulic system began

losing pressure, and the XB-70 headed back to Edwards. By the time she was

on her final approach, the landing gear had to be lowered using the

emergency electrical system. The actual touchdown on the lakebed was

uneventful, and the XB-70 rolled to a stop after 10,000 feet.

A week later, on October 12th, 1964, the Valkyrie burst through the sound

barrier for the first time, reaching a speed of Mach 1.1 before decelerating

beneath the sound barrier and breaking back through several times to check

trans-sonic stability.

October 24th, 1964, represented the Valkyrie's last flight for a

while.

Returning to North American's Palmdale facility at the end of this flight,

the XB-70 was scheduled to go through a series of structural tests that

would not return her to the flight line until February of 1965.

AV/1 returned to flight on February 16th, 1965. This flight would

return the XB-70 to Edwards AFB (about 30 miles by air from North American's

Palmdale facility). For the first time, the wingtips were lowered to the

The sixth flight was the first time someone other than Al White and Joe

Cotton were at the controls. Lt. Col. Fitzhugh "Fitz" Fulton (later to be

NASA's Chief Test Pilot) flew as co-pilot with Al White as pilot. But again,

hydraulic leaks cut this flight short. Engineers at North American worked

continuously to modify the hydraulic systems (which operated at 4000psi,

more than 35% greater pressure than any other aircraft's system) to end the

constant problems of leakage that had disrupted almost every flight.

Although these changes were never totally effective on AV/1, AV/2

benefited greatly from the misfortunes suffered by the first plane.

During the seventh flight, on March 4th, White and Fulton shattered records

again, sustaining supersonic flight for 60 minutes, reaching a top speed of

Mach 1.85. The eighth flight introduced the last of the four pilots, North

American's Van Shepard, to the aircraft, and saw Mach 2 fall to the six J93

engines. The eighth flight also demonstrated how quickly Mach 2 could take

the Valkyrie where the pilots didn't plan on going, as a momentary glitch in

the single TACAN system led to an inadvertent "booming" of Las Vegas that

early morning. On the tenth flight, the Valkyrie sustained 74 minutes of

supersonic flight, including 50 minutes beyond Mach 2!

Externally, the difference was obvious -- the wings had been given 5 degrees

of dihedral. This change was a result of testing that showed AV/1 to have

poor roll stability at high speed with the wingtips fully lowered. The

tradeoff was that, at low speeds with the wingtips up, AV/2 suffered from

severe "dihedral effect" -- a situation where sideslip causes the plane to

drop one wing. The pilot, sensing the low wing but not spotting the

sideslip, would use the ailerons to try and bring the wing back up -- which

actually caused MORE sideslip, forcing the wing to drop lower! (this is a

very difficult thing to visualize -- it took me several hours to get it

straight in my head) One pilot remarked "it felt like being backed into a

corner." The only solution was for pilots to closely watch the sideslip

indicator.

October 14th, 1965.

After 56 weeks and 17 flights, AV/1 had finally reached her goals -- but she

would never fly at Mach 3 again. The design team, alarmed with the

skin separation problems, and knowing that improvements in AV/2 would solve the

problem, decided that from that point on, AV/1 would be limited to a

maximum speed of Mach 2.5. Mach 3 research would be left to the

improved, and more capable, second aircraft.

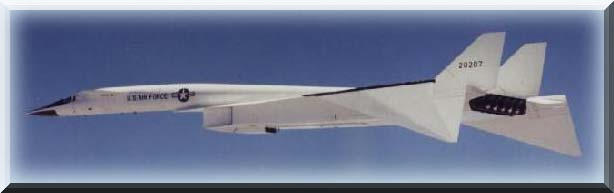

Initially, AV/2 (tail number 20207) wasn't completely trouble-free. Brake

chatter continued to be a problem during low-speed taxiing, although it was

suspected that this stemmed from the lack of return springs for the brake

pads (like automobiles, the Valkyrie was designed for the pads to lightly

touch the rotors at all times). Far more troubling, however, were problems

in the new, automatic AICS system, which would inexplicably recycle during

supersonic flight, causing an "unstart," where the shockwave from the

forward fuselage, rather than being deflected past the inlet and under the

wing, instead fell directly into the inlet. Not only did this change in

inlet airflow cause a brief flameout on the engines, but it also caused a

sharp roll in the direction of the GOOD engine set. For pilots, this is

fairly odd behavior caused by the shape of the XB-70's wing, combined with

the lowered tips (and on Ship One, accentuated by the lack of dihedral),

which as the aircraft yawed to the "dead" side, caused a roll away into the

"good" side. So, during an unstart (described by Fitz Fulton as "being

T-boned by a locomotive and thrown off a cliff"), the pilot would have to

apply rudder into the direction of the roll, which is a bit unnatural

[Ed. note -- and I would assume quite unnerving as well!]

Sometimes, speed and throat ramp settings would create a condition where the

shockwave was right at the boundary of the inlet, jumping in and out. This

"buzz" was a serious condition that had to be rectified immediately -- left

to continue for more than a few moments, the stresses could have torn the

XB-70 apart! Following the 8th flight of AV/2, Al White stated in his pilot's

report that he didn't feel comfortable trying for Mach 3 until the AICS was

sorted out, which took several additional flights.

As this was sorted out, concerns were voiced that AV/2 might also suffer

skin separation problems under the heating caused by sustained high-speed

flight, despite the improved construction and assembly techniques. It was

decided that with AV/2, early flights would involve "heat-soaking" at speeds

less than Mach 3. This way, unlike a quicker "dash" up to speed, the

airframe would reach the full temperature created by flight at that speed.

Heat is the major enemy of speed. Caused by the friction of cutting through

the air, heat has limited the top speed of modern aircraft (such as the

F-15) far more than power. Beyond Mach 2.5, friction increases at an

ever-growing rate (for comparison, an SR-71 operating at Mach 2.2 heats up

to about 275 degrees, but at Mach 3.2, skin temperatures rise to almost 900

degrees!). The same aerodynamics that gave the XB-70 so little drag helped

minimize heat buildup. The hottest portions of the Valkyrie, her nose and

horizontal splitter, reached a temperature of only 625 degrees during Mach 3

flight, with the majority of the XB-70's skin at a temperature of just 450

degrees! Equipment was placed in the fuel tanks, which acted as heat sinks.

As the fuel soaked up the heat from the fuselage, it was drawn into the

engines and burned away, leaving the cooler fuel behind. At the same time,

it had to be replaced with nitrogen gas. The temperatures inside the tanks

were high enough that just two percent oxygen would have caused the fuel to

burst into flames -- a decidedly undesirable event.

On her 15th flight, on December 11th, 1965, AV/2 ran at Mach 2.8 for 20

minutes (spending 41 total minutes beyond Mach 2.5) without any indications

of skin separation. Ten days later, after seven minutes at Mach 2.9 (and 20

minutes above Mach 2.8), the oil pump for the number four engine failed.

Shutting down the engine, White and Cotton headed back to Edwards, when an

overtemperature caution came on for the number six engine, which was shut

down as well. After landing, it was discovered that, despite the early

shutdown, loss of lubrication had ruined engine number four -- an unhappy

moment in a flight program that now only had 29 engines left (with 12 needed

just to get the two planes in the air!). The number six engine was removed and

sent off to General Electric for rebuilding.

Engine installation was another ground-breaking feature of the XB-70. Unlike other

airplanes, where all the engine's accessories were bolted to the plane, and

then connected to the engine (making removal a tedious job), on the

Valkyrie, everything was bolted to the engine itself, making engine removal

and replacement a job that could be done in just a couple of hours.

Today, many military and commercial planes use this design.

Less than 6 months after her first flight, AV/2 reached her goal of Mach 3,

on her 17th flight (coincidently, the same number of flights AV/1 to reach

Mach 3). Just for three minutes, then back home for a thorough examination.

No sign of skin damage at all! Prudence was still the watchword, however,

and AV/2 twice more poked her sleek nose beyond Mach 3 for just a few

minutes before sustaining Mach 3 for 15 minutes on her 22nd flight.

Feeling secure that AV/2 would not have the same skin separation problems of

AV/1, extensive performance and control testing at speeds above Mach 2.7,

but below Mach 3 were the next step. This data was important for

determining what the handling abilities of the SST (intended to cruise at

around Mach 2.7) would be like. Already, it had become obvious that no SST

could be expected to use the established approach routes to airports! Some

sonic boom testing (although not as extensive as later on) was also

conducted. The viability of the SST depended on high-altitude sonic booms

being greatly dissipated as compared to lower altitude sonic boom effects.

To the dismay of many, early tests indicated this would not be the case.

At this point in March, 1966, AV/1 was getting ready for her 37th flight,

with Van Shepard as pilot, and Joe Cotton as co-pilot. Control and

performance tests were on the flight plan -- but soon it was a different

performance being tested.

Halfway through the planned flight, BOTH hydraulic systems -- primary and

secondary -- began to fail. Shepard quickly brought the Valkyrie home as

Cotton extended the landing gear. No green indicators came on, followed by

a call from the chase plane that there was trouble with both sets of main

gear. On the left side, the gear hadn't fully lowered before rotating to

meet the direction of travel, leaving her rear wheels higher, rather than

lower, than the front set of wheels.

Van Shepard gingerly set AV/1 down on the lakebed, and each main gear did

what the engineers expected. So now, the plane was down and rolling, but

she wanted to turn sharply to the right -- threatening to ground loop,

which, although likely not fatal to the pilots, would likely destroy the

aircraft. So Shepard kept applying power to the number six (farthest right

side) engine to help keep the XB-70 somewhat straight, but at the same time,

he couldn't use too much power, or the plane would never stop!

Finally, after rolling almost three miles, the XB-70 completed her landing run,

which, when viewed from above, looked like an upside-down letter "J" because

the XB-70 had not just swung over half a mile to the right side, but by the

time she came to a stop, she had turned 110 degrees, almost pointing in the

direction she had come from! Only the huge size of the lakebed made

this landing possible --anywhere else, the XB-70 would have been

far off the runway and likely into buildings and hangars (another decidedly

undesirable event).

Later that same month, to the joy of a great many Texans, it was decided

that AV/2 would be flown down to Carswell AFB for the airshow there.

It was to be the only airfield that Ship Two would fly to and return.

With Fitz Fulton at the controls, the Valkyrie spent only 13 minutes at Mach

2.6 before slowing up, winding up at 6,000 feet over Carswell AFB just 59

minutes after takeoff! For the next half hour, AV/2 thundered around the

skies of Texas before landing. The return flight two days later was the

only flight during the entire program where performance data was not

recorded, as Cotton (in the pilot's seat) and White flew back at subsonic

speeds, taking a little over three hours to return to Edwards.

Then AV/2 was off to heatsoak for even longer times -- over 30 minutes -- at

speeds of Mach 2.8 and 2.9, as well as flights of 16 and 20 minutes at Mach

3. Flights 35 and 36 were used to get a better look at the causes and ways

to remedy unstarts at speeds above Mach 2.5.

April 30th, 1966.

Al White and Joe Cotton prepared to take AV/2 past the final hurdle to having

"unlimited" status for Mach 3 flight -- a 30+ minute run at Mach 3 to fully

heatsoak all systems. Shortly after takeoff, Cotton retracted the landing

gear. The nose gear jammed into its door, and as good as things had been

going, they were going bad now. The attempt to lower the gear using the

normal hydraulic system failed. Trying the backup electrical system, Cotton

heard a "pop" as THAT system went dead. Given the Valkyrie's long, graceful

neck, and the intake design, retracting the main gear and landing on her

belly wasn't possible -- in fact, it was so impossible that North American

had never attemped to simulate it!

White first brought the XB-70 around for a touch-and-go, hoping that a hard

impact on the main gear would knock the nose gear loose and let it fall to

But there was fuel to burn away in any case, so while people on the ground

pulled out plans and diagrams, White and Cotton circled around Edwards

slowly but surely. Finally, Cotton was sent to the back of the cockpit to

open service panels and check on things for the people below. After more

than an hour of this (and 2 hours of flying), the problem with the backup

system was traced -- hopefully -- to a circuit breaker. Now all Cotton had

to do was find a way to short circuit the unit by closing two contacts. Of

course, the Valkyrie had no on-board toolkit -- that would have made things

too simple. But Cotton HAD brought along his briefcase with his various

notes and plans, and opening it, he found a good, thick paperclip (actually,

it was part of a legal-style paperclip, not a conventional one)

. [Ed. note: Now that I've had to opportunity to see the cockpit of the B-70,

-- and the small crawl space that Joe Cotton had to go through in a full

pressure suit, all I can say is "wow!"] Straightening out the paperclip,

then grasping the middle of it with a leather glove, Cotton carefully

reached in and ZAP! short circuited the breaker. As Al White hit the switch

to extend the gear, and was rewarded with the sound of a working backup

system, Cotton gratefully dropped into his seat. As several newspapers

exclaimed the following day, a "39 cent paperclip saves $750 million

aircraft!"

And indeed it had.

In the landing, however, the main gear bogies had been damaged, and would

take two weeks to repair -- although this was a tiny price compared to

losing the aircraft. Unbeknownst to everyone involved, the loss of the

AV/2 wasn't avoided, but merely postponed a little longer.

Finally, on May 19th, flight number 39, AV/2 flew at Mach 3 for 33 minutes,

and a total of 62 minutes beyond Mach 2.5. In just 91 minutes, the Valkyrie

traveled over 2,400 miles -- an average speed of more than 1500 miles per

hour, including takeoff and landing! Finally, all remaining concerns about

skin separation were laid to rest. The improved methods used to build AV/2

were more than up to the task of sustained Mach 3 flight.

After this, AV/2 flew to test stability and control at subsonic and

supersonic speeds. On May 22nd, 1966 [Ed. note -- exactly one year before I

was born!], AV/2 thrilled the spectators at the Armed Forces Day show at

Edwards, including a couple of supersonic passes over the crowd.

At this point, with all systems tested, the XB-70 program prepared to move

into Phase 2, where NASA would become much more involved, and extensive

sonic boom and handling tests would begin. New pilots would join the

program, including NASA Chief Test Pilot Joe Walker, who

had just wound down the X-15 program. Not only did Walker have an

"astronaut" rating (given to any pilot who flew higher than 50 miles, which

the X-15 did), he had flown the X-15 beyond Mach 6 (4,100mph) in level

flight (a later flight by Pete Knight with external tanks did more then

4,500mph). Also joining the program was USAF Major Carl Cross.

At the same time, both Al White and Joe Cotton would gradually ease out

of the program, with Cotton going on to test newer planes for the Air Force,

and White to work on other projects at North American. The Valkyrie

had reached her goals, and been tested successfully. Al White had

achieved his goals for the XB-70 program.

In preparation for Phase 2, AV/2 was refitted with even more data recording

equipment, costing more than $50 million. These instruments would give a

better look at a number of phenomena that couldn't be thoroughly tested in a

wind tunnel -- information regarding body flex, flutter, and pressure. At

the same time, NASA began setting up a large number of ground sensors to

precisely measure the effect of sonic booms.

Major Carl Cross sits in the Valkyrie's cockpit for the first time, with Al

White in the pilot's seat. For Carl Cross, getting into the B-70 program is

the high point of his career. Worried about making the best

impression and not making mistakes, he has studied hard and long.

On this morning, before his first flight, he even asks Joe Cotton to meet

him at the aircraft an hour before anyone else will get there, so they can

sit in the cockpit and run through everything one last time before flight.

The flight plan for today is simple: they will make several passes over

recording instruments at a speed of Mach 1.4 at 32,000 feet, then, at the

request of General Electric, they will fly in formation with 4 other

GE-powered aircraft so that GE photographers can take some publicity

pictures from an accompanying Learjet. The boom-testing went smoothly,

then, dropping subsonic speed and raising the wingtips back to 25 degrees,

the Valkyrie joined up in formation with the other aircraft, including, just

off her right wingtip, an F-104 Starfighter piloted by Joe Walker.

Disaster struck at this moment as somehow, Walker's F-104 collided

Al White and Carl Cross heard the impact, but felt nothing. Flying in the

T-38 off the left wingtip, Joe Cotton called out "207 (identifying AV/2)

you've been hit! You've been hit!" But in those first moments, neither

White nor Cross heard the call. Even as Cotton continued "...okay, you're

doing fine, he got the verticals, but you're still doing fine," White turned

to Cross and asked, "I wonder who got hit?"

16 seconds after the impact, the XB-70 started a slight roll. Al White

corrected the roll -- and instantly recognized the Valkyrie's peril as she

began a snap roll to the right. Ramming the number six engine's throttle to

maximum afterburner, he tried to save AV/2 -- but after 2 slow rolls, the

plane broke into a sickening spin, taking any hopes of recovery with it.

White pushed his seat back into the eject position, but caught his arm in

Although the drogue chutes deployed from White's pod, he realized the airbag

underneath the pod -- designed to absorb much of the impact -- had failed to

inflate. Striking the ground, White took a 44G impact -- lessened to 33Gs

as his chair broke free of its mountings. Amazingly, although banged,

battered, and bruised, he suffered no broken bones. Although White returned

to flight status just three months later, he never flew the XB-70 again.

Carl Cross was not so lucky. Unable to escape the Valkyrie, and still

strapped into his seat, he was killed instantly when the B-70 struck the

ground in an upright and level configuration.

Both the USAF and NASA were unsure that AV/1, with her Mach 2.5 speed

limitation and general gremlin troubles, could perform the research intended

for AV/2. Ultimately, after a few more flights, the Air Force bowed out of

the XB-70 program, leaving NASA to carry

Finally, on February 4th, 1969, AV/1 took off for her eighty-second, and

final flight, to the Air Force Museum at Wright Field, in Dayton, Ohio.

Gathering data throughout the entire flight, Fitz Fulton and Emil Sturmthal

made a pass over the runway before bringing the XB-70 down for a perfect

landing, then, handing the logbook to the museum curator, officially brought

the XB-70 program to an end. [Ed. note - Emil Sturmthal is credited with having said

"I'd do anything to keep the Valkyrie flying -- except pay for it

myself"] Today, the Valkyrie resides inside the R&D hangar, finally

protected from the ravages of time.

But the Valkyrie was more than just an airplane. It was a complete package

that advanced aerodynamic design, created the template for honeycomb

construction, and allowed for extensive testing almost a decade before the

first SR-71 appeared at an airshow. In addition, the YF-12 and SR-71 were never

destined for mass production -- their cost was far too high with the

composite and titanium skin, and maintenance costs off the charts (In 1991,

with just a few airframes in service, the USAF still spent more than $400

million on maintaining the Blackbird).

Much of the costs related to the XB-70 would have easily been amortized out

had production ever become a reality. And there were few true vices in the

aircraft itself that would not have been sorted out. While the early

hydraulics layout on AV/1 was highly problematic and disruptive, those

problems, as well as the skin bonding issues, were almost completely

eradicated on Ship Two. And neither of the truly complex systems, such as

the wing hinges, or the engine intakes ever generated issues in flight --

despite some pessimistic predictions that those systems would be the undoing

of the program. (Admittedly, the wing hinges themselves had to be replaced

at one point due to a corrosion issue in the alloy used, but in flight, the

system never hiccupped) The J93 engines, the tooling to build the airframes

-- all of this normally would have been spread across hundreds of aircraft.

Indeed, indirectly, the research from the program went on to benefit many

aircraft, from supersonic fighters to mundane commercial jetliners. Had AV/2

not been lost, there would certainly have been many, many more flights. But

even with the limited flights, and the use of AV/1 at the end of the

program, a significant amount of experience and knowledge of the future SST

was acquired. Even though we don't think about it, the Valkyrie effectively

killed the SST program by showing that supersonic flight by airliners, no

matter how high they flew, would produce too great a sonic boom at ground level

to ever be acceptable.

Modern test programs have involved high angles of attack, improved control,

and many other features important to the planes of tomorrow. But unlike the

Valkyrie, they represent advances into the known, enhancements of what

aircraft are capable of today. The Valkyrie was conceived in 1959, a year

when the Air Force was getting its first Mach 2 fighter (ironically, the

F-104 Starfighter), yet here was a program calling for a Mach 3 bomber with

long range endurance. And despite never being truly optimized from flight

data, the program developed a plane that could take off weighing more than

538,000 pounds, and cruise at three times the speed of sound.

For me, the magic of the Valkyrie is not just in what she accomplished, but

in how far she reached to accomplish it.

Copyright Information: All pictures included are public domain.

The text and entire page as a whole may be freely used for non-profit

purposes, although I would like my email address to remain at the bottom of

the page. For-profit use of this page requires my explicit permission.

Here is a

link to common phrases and names that old friends might be looking for me

under.

.

.  .

.

Total vertical area was increased,

allowing shorter vertical stabilizers than would otherwise be needed.

Total vertical area was increased,

allowing shorter vertical stabilizers than would otherwise be needed.

The reduction in rearward wing area

countered the delta wing's inherent rearward shift of the center of lift as

speed increased, keeping drag-inducing trim corrections to a minimum.

The reduction in rearward wing area

countered the delta wing's inherent rearward shift of the center of lift as

speed increased, keeping drag-inducing trim corrections to a minimum.

Compression lift was 30 percent more

effective because the pressure under the wing was better managed.

Compression lift was 30 percent more

effective because the pressure under the wing was better managed.

XB-70 number one, with the tail number 20001 (generally referred to as AV/1

(Air Vehicle/1) or Ship 1) was rolled out of its hangar at North American's

Palmdale, California facility and into the public's view on a bright and

sunny May 11th, 1964. Just sitting on the ground, the Valkyrie awed the

audience. Her long, graceful neck over their heads, air intakes a man could

stand in (and 80' long -- longer than an SR-71!), and sleek lines left no

doubt she was designed for speed. But just two months later, the budget axe

took its swing, chopping AV/3 (which was in the early stages of

construction) out of the program, and, unknowingly, crippled the entire

XB-70 program.

XB-70 number one, with the tail number 20001 (generally referred to as AV/1

(Air Vehicle/1) or Ship 1) was rolled out of its hangar at North American's

Palmdale, California facility and into the public's view on a bright and

sunny May 11th, 1964. Just sitting on the ground, the Valkyrie awed the

audience. Her long, graceful neck over their heads, air intakes a man could

stand in (and 80' long -- longer than an SR-71!), and sleek lines left no

doubt she was designed for speed. But just two months later, the budget axe

took its swing, chopping AV/3 (which was in the early stages of

construction) out of the program, and, unknowingly, crippled the entire

XB-70 program.

Two pilots from North American were chosen to fly the B-70 during the

development phase. Al White, who had just wrapped up the F-107 program

(with the innovative sidestick that would not reappear for almost twenty

years), and Van Shepard. Interestingly enough, Al White had very limited

experience in large aircraft, but was chosen because of the systems

complexity of the B-70. The USAF, on the other hand, pulled its two pilots

from the team which helped bring the Mach 2 B-58 into operational service,

Colonel Joe Cotton and Major Fitz Fulton. To provide both high-speed chase

as well as large, delta wing training and experience, a TB-58 was

essentially "adopted" by the program (and interestingly enough, in later

years, was used to give Brian Trubshaw, BAe's Chief Test Pilot for the

Concorde, some experience as well).

Two pilots from North American were chosen to fly the B-70 during the

development phase. Al White, who had just wrapped up the F-107 program

(with the innovative sidestick that would not reappear for almost twenty

years), and Van Shepard. Interestingly enough, Al White had very limited

experience in large aircraft, but was chosen because of the systems

complexity of the B-70. The USAF, on the other hand, pulled its two pilots

from the team which helped bring the Mach 2 B-58 into operational service,

Colonel Joe Cotton and Major Fitz Fulton. To provide both high-speed chase

as well as large, delta wing training and experience, a TB-58 was

essentially "adopted" by the program (and interestingly enough, in later

years, was used to give Brian Trubshaw, BAe's Chief Test Pilot for the

Concorde, some experience as well).

Finally, at 8:24, the Valkyrie is aligned on the runway. Al White advances

the six throttles to maximum afterburner, and the XB-70 begins its takeoff

run. At 193mph, White rotates the long neck of the XB-70 into the air,

establishing a nine degree Angle-of-Attack for the wing. At 205mph and 4,853

feet of runway, the 387,620 pounds of the Valkyrie lifts into the blue sky

for the first time. Per the flight plan, speed was held at 310mph and the

gear left down for the flight to Edwards. No unusual handling problems

occurred during this time.

Finally, at 8:24, the Valkyrie is aligned on the runway. Al White advances

the six throttles to maximum afterburner, and the XB-70 begins its takeoff

run. At 193mph, White rotates the long neck of the XB-70 into the air,

establishing a nine degree Angle-of-Attack for the wing. At 205mph and 4,853

feet of runway, the 387,620 pounds of the Valkyrie lifts into the blue sky

for the first time. Per the flight plan, speed was held at 310mph and the

gear left down for the flight to Edwards. No unusual handling problems

occurred during this time.

delta wing, it was difficult for the pilots to judge their altitude above

the runway, or the actual point of touchdown (it was not until the tenth

flight that Al White stopped using the chase planes to call out his

altitude). Aiming for touchdown 2,000 feet down the long runway, White smoothly

set the XB-70 on the ground.

delta wing, it was difficult for the pilots to judge their altitude above

the runway, or the actual point of touchdown (it was not until the tenth

flight that Al White stopped using the chase planes to call out his

altitude). Aiming for touchdown 2,000 feet down the long runway, White smoothly

set the XB-70 on the ground.

Colonel Joe Cotton, sitting in the co-pilot's seat, reached over

and moved the control knob innocuously labeled "tip fold" to the 25 degree

mark. Slowly and smoothly on their massive, H-11 steel hinges, the wingtips

lowered themselves to the 25 degree position for the first time. Reaching a

maximum speed of Mach 1.4, the XB-70 remained supersonic for 40 continuous

minutes, establishing a new world's record for sustained supersonic flight.

The overall time of the flight was cut short, as fuel consumption proved to

be higher than expected.

Colonel Joe Cotton, sitting in the co-pilot's seat, reached over

and moved the control knob innocuously labeled "tip fold" to the 25 degree

mark. Slowly and smoothly on their massive, H-11 steel hinges, the wingtips

lowered themselves to the 25 degree position for the first time. Reaching a

maximum speed of Mach 1.4, the XB-70 remained supersonic for 40 continuous

minutes, establishing a new world's record for sustained supersonic flight.

The overall time of the flight was cut short, as fuel consumption proved to

be higher than expected.

Upon returning to Palmdale, engineers puzzled over why the Valkyrie had been

shedding herself of paint on all but her first flight. Although not overly

concerned, no one was especially happy with unexplainable things on a plane

that was to test the limits of jet-powered flight! Although some observers

wondered if the Air Force was being entirely truthful about the XB-70's top

speed, it was finally determined that too-thick paint caused by several

re-paintings (in order to pretty the plane up for various VIPs) was being

cracked as the Valkyrie flexed in flight, and was then torn away by the

airstream. During her winter stay at Plant 42, the XB-70 was carefully

repainted with just a single, thin coat of white paint.

Upon returning to Palmdale, engineers puzzled over why the Valkyrie had been

shedding herself of paint on all but her first flight. Although not overly

concerned, no one was especially happy with unexplainable things on a plane

that was to test the limits of jet-powered flight! Although some observers

wondered if the Air Force was being entirely truthful about the XB-70's top

speed, it was finally determined that too-thick paint caused by several

re-paintings (in order to pretty the plane up for various VIPs) was being

cracked as the Valkyrie flexed in flight, and was then torn away by the

airstream. During her winter stay at Plant 42, the XB-70 was carefully

repainted with just a single, thin coat of white paint.

full 65 degree mark. Accelerating to Mach 1.6, Joe Cotton then adjusted the

AICS (Air Induction Control System) -- The series of ramps inside the

intakes which would expand and contract to manipulate airflow to the engines

and protect them from the deadly onslaught of high-speed air. After another

40 minutes of supersonic flight, the Valkyrie landed, but with the drag

chutes failing to deploy, the landing run was over 11,100 feet.

full 65 degree mark. Accelerating to Mach 1.6, Joe Cotton then adjusted the

AICS (Air Induction Control System) -- The series of ramps inside the

intakes which would expand and contract to manipulate airflow to the engines

and protect them from the deadly onslaught of high-speed air. After another

40 minutes of supersonic flight, the Valkyrie landed, but with the drag

chutes failing to deploy, the landing run was over 11,100 feet.

May 7th, 1965 was AV/1's 12th flight, with Al White and Fitz Fulton at

the controls. Traveling at Mach 2.58 (almost 1700mph!), a 'thump' was heard

May 7th, 1965 was AV/1's 12th flight, with Al White and Fitz Fulton at

the controls. Traveling at Mach 2.58 (almost 1700mph!), a 'thump' was heard

in the cockpit, soon followed by a number of engine-related alarms. Engines

three, four, five, and six were shut down right away. As the chase planes

caught up, they reported that the horizontal splitter (the very apex of the

in the cockpit, soon followed by a number of engine-related alarms. Engines

three, four, five, and six were shut down right away. As the chase planes

caught up, they reported that the horizontal splitter (the very apex of the

delta wing) had torn away. Wind tunnel testing and theory said that the

splitter would only face upward loads. Reality proved different, as sharp

downward loads caused the splitter to break up, with debris going into the

engine intakes and doing severe damage to the engines. For the final

approach, the number five engine was restarted to provide some thrust from

the right side, and the XB-70 landed on the long lakebed without major

incident. All six engines, nearly one-sixth of the 38 ever built, were

destroyed beyond repair. After this flight, the splitter itself was

replaced with a single solid piece in place of the honeycomb unit that had

failed. At this point, concerns about the integrity of the honeycomb skin

began, and the next 4 flights concerned themselves with "heat soaking" the

skin for sustained periods of time. For the first time, the XB-70's ability

to reach Mach 3 was questioned.

delta wing) had torn away. Wind tunnel testing and theory said that the

splitter would only face upward loads. Reality proved different, as sharp

downward loads caused the splitter to break up, with debris going into the

engine intakes and doing severe damage to the engines. For the final

approach, the number five engine was restarted to provide some thrust from

the right side, and the XB-70 landed on the long lakebed without major

incident. All six engines, nearly one-sixth of the 38 ever built, were

destroyed beyond repair. After this flight, the splitter itself was

replaced with a single solid piece in place of the honeycomb unit that had

failed. At this point, concerns about the integrity of the honeycomb skin

began, and the next 4 flights concerned themselves with "heat soaking" the

skin for sustained periods of time. For the first time, the XB-70's ability

to reach Mach 3 was questioned.

AV/2 (tail number 20207) made its first flight on July

17th, 1965. Lacking the gremlins of AV/1's first flight, the wingtips

were lowered 65 degrees, and a top speed of Mach 1.4 was reached before

landing at Edwards AFB. AV/2 differed from her older sibling, inside and

out. Internally, a more flexible system of hydraulic fittings were used, to

reduce the leaking that continued to trouble AV/1. The techniques to build

the honeycomb skin had improved with experience, and hopefully AV/2 would

not suffer any of the troubles AV/1 was undergoing. The fuel tanks on AV/2

were inspected very carefully, to avoid the internal leakage problems which

ultimately rendered AV/1's number five (centerline fuselage) unusable.

AV/2 (tail number 20207) made its first flight on July

17th, 1965. Lacking the gremlins of AV/1's first flight, the wingtips

were lowered 65 degrees, and a top speed of Mach 1.4 was reached before

landing at Edwards AFB. AV/2 differed from her older sibling, inside and

out. Internally, a more flexible system of hydraulic fittings were used, to

reduce the leaking that continued to trouble AV/1. The techniques to build

the honeycomb skin had improved with experience, and hopefully AV/2 would

not suffer any of the troubles AV/1 was undergoing. The fuel tanks on AV/2

were inspected very carefully, to avoid the internal leakage problems which

ultimately rendered AV/1's number five (centerline fuselage) unusable.

An automatic control for the AICS was installed, in place of AV/1's manual

system, which used a grid of speed and altitude that the pilots used as a

reference to set the actual ramp position.

An automatic control for the AICS was installed, in place of AV/1's manual

system, which used a grid of speed and altitude that the pilots used as a

reference to set the actual ramp position.

Another instrumentation problem cropped up during high-speed flight. At Mach

3, just one degree of pitch would send the XB-70 into a 3,000 foot

per minute change of altitude. Combined with raising the noseramp

(windscreen assembly) to the "supersonic" position, which blocked the

pilots' view of the horizon (and tended to reflect the ground below, leading

to several complaints of vertigo), the Valkyrie was virtually impossible to

keep at a fixed altitude. Eventually, a highly sensitive rate-of-climb

meter from a helicopter was installed to help (but not entirely fix) this

problem.

"On this flight the XB-70 proved its capability of attaining Mach 3 at

70,000 feet!" -- Al White's summary in the pilot's report for

Flight 1-17.

As AV/1 crossed the Mach 3 threshold, her nose abruptly pitched upwards.

But even as Al White corrected, the nose just as sharply pitched downward.

Combined with the correction, the XB-70 accelerated just enough to cause a

brief moment of overpressure in the inlets. Stabilizing the Valkyrie, Al

White keyed his microphone and spoke the words everyone had been waiting

for, "There's that big magic number [Mach 3]." For almost three minutes,

everything appeared fine. Suddenly, White and Cotton heard something behind

them. Although no caution lights had come on, and concerned about damage

caused by the overpressure, White decided to decelerate and let the chase

planes catch up with the XB-70. When they did, they reported that about 2

feet of the left wing's leading edge was missing. Fortunately, the damaged

section of the wing was far enough outboard that the debris wasn't drawn

into the engine inlets. [Ed. note - it was on this flight that the

Valkyrie carried a special cargo -- a bag of Idaho potatoes which were later

presented to the small town of Brawley, Idaho, which had accepted being

under the XB-70's flight path and being "boomed" all the time with smiles

and good humor]

After what must have seemed like hours in the cockpit, engineers on the

ground called up to the pilots with their plan. Shepard would land the

Valkyrie on the dry lakebed, so there would be plenty of room to ease to a

stop. It was felt that, on touchdown, the left side gear would level itself

out, the sheer weight of the XB-70 forcing the gear into its normal

position. As for the right gear... being behind the centerline of the main

strut, it was unlikely that the gear would level out, but hopefully

the landing would at least cause the gear to finish swinging into the

direction of travel, and the wingtip would still clear the ground, although

the right side would be much lower than the left.

After what must have seemed like hours in the cockpit, engineers on the

ground called up to the pilots with their plan. Shepard would land the

Valkyrie on the dry lakebed, so there would be plenty of room to ease to a

stop. It was felt that, on touchdown, the left side gear would level itself

out, the sheer weight of the XB-70 forcing the gear into its normal

position. As for the right gear... being behind the centerline of the main

strut, it was unlikely that the gear would level out, but hopefully

the landing would at least cause the gear to finish swinging into the

direction of travel, and the wingtip would still clear the ground, although

the right side would be much lower than the left.

the extended position. Even after a second try, however, the nose gear

remained jammed. At this point, bailing out and losing the aircraft was

quickly becoming the only option.

the extended position. Even after a second try, however, the nose gear

remained jammed. At this point, bailing out and losing the aircraft was

quickly becoming the only option.

with the Valkyrie. The complex airflow surrounding the XB-70 lifted the

F-104 over her back, spun the Starfighter around 180 degrees, causing it to

smash down along the center of the Valkyrie's wing, tearing off both

vertical stabilizers and damaging the left wingtip before falling away in

flames. Already, Joe Walker, one of America's great test pilots, was dead.

with the Valkyrie. The complex airflow surrounding the XB-70 lifted the

F-104 over her back, spun the Starfighter around 180 degrees, causing it to

smash down along the center of the Valkyrie's wing, tearing off both

vertical stabilizers and damaging the left wingtip before falling away in

flames. Already, Joe Walker, one of America's great test pilots, was dead.

"Midair! Midair! Midair!"

the ejection pod's

clamshell doors (see inset photo at left) as they closed. Unable to

communicate with the struggling Carl Cross, and unable to eject until

getting his arm clear, White could only watch his co-pilot fail to get into

his pod for ejection. Finally, with the realization that he needed to get

out now, Al White worked his arm clear and ejected just moments

before AV/2 slammed into the ground a few miles north of Barstow,

California.

the ejection pod's

clamshell doors (see inset photo at left) as they closed. Unable to

communicate with the struggling Carl Cross, and unable to eject until

getting his arm clear, White could only watch his co-pilot fail to get into

his pod for ejection. Finally, with the realization that he needed to get

out now, Al White worked his arm clear and ejected just moments

before AV/2 slammed into the ground a few miles north of Barstow,

California.

ejection system to make it easier, and the installation of modified brakes

to allow for return springs for the brake pads. Unsurprisingly, the brake

modification cured the problem of brake chatter at low speeds. The

instrumentation package was upgraded to a system similar to the package

installed on AV/2.

ejection system to make it easier, and the installation of modified brakes

to allow for return springs for the brake pads. Unsurprisingly, the brake

modification cured the problem of brake chatter at low speeds. The

instrumentation package was upgraded to a system similar to the package

installed on AV/2.

on additional flights on its own. Although not doing as well as AV/2 would

have, the older Valkyrie soldiered on for 33 additional flights, garnering

valuable data about both high-speed flight, as well as preliminary data

about flying conventional landing approaches in a large delta wing aircraft,

in preparation for the American SST, which was still on the drawing boards

at Boeing.

on additional flights on its own. Although not doing as well as AV/2 would

have, the older Valkyrie soldiered on for 33 additional flights, garnering

valuable data about both high-speed flight, as well as preliminary data

about flying conventional landing approaches in a large delta wing aircraft,

in preparation for the American SST, which was still on the drawing boards

at Boeing.

Questions or comments? Mail me at steven.levin@interceptor.com.